From Winterthur to the world

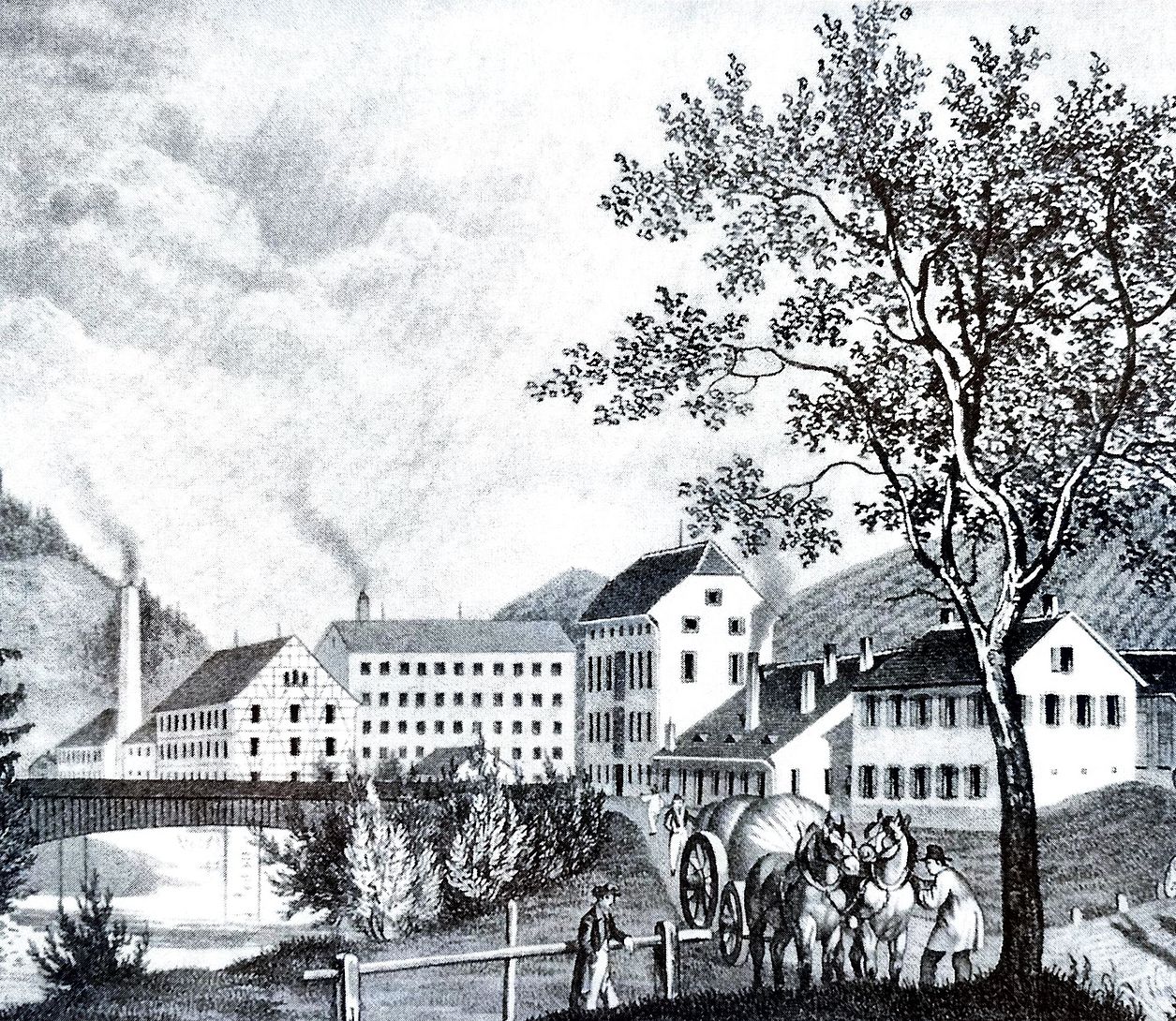

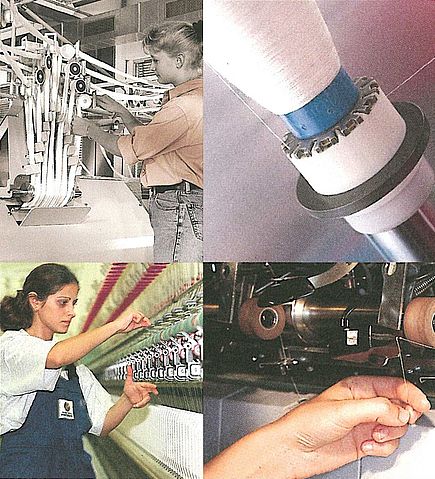

In April 1795, Johann Jacob Rieter founded a company in Winterthur trading exotic spices and cotton. Today, the company develops machinery and systems for the textile industry worldwide.

ITMA in Milan: with the 200th anniversary comes a fresh new look

In its anniversary year, Rieter introduces a new design and concept at the textile technology trade fair ITMA. Instead of primarily showcasing machines, the focus is on personal interaction. ITMA in Europe takes place every four years and is the biggest textile industry trade fair in the world.

June 1995

Rieter Automotive: leaping the Atlantic in the wake of globalization

With the acquisition of the US automotive supplier Globe, the Rieter Group makes the largest acquisition in its history and takes a decisive strategic step. With plants in the USA and Canada, Globe supplies domestic car manufacturers as well as Japanese competitors.

Dual strategy: Unikeller becomes Rieter Automotive Systems

As it enters the North American market, the automotive supply business gives up its historical name Unikeller and becomes Rieter Automotive Systems, following the same pattern as Rieter Textile Systems for the textile machinery business. The names reflect the strategy: Rieter wants to develop both businesses equally.

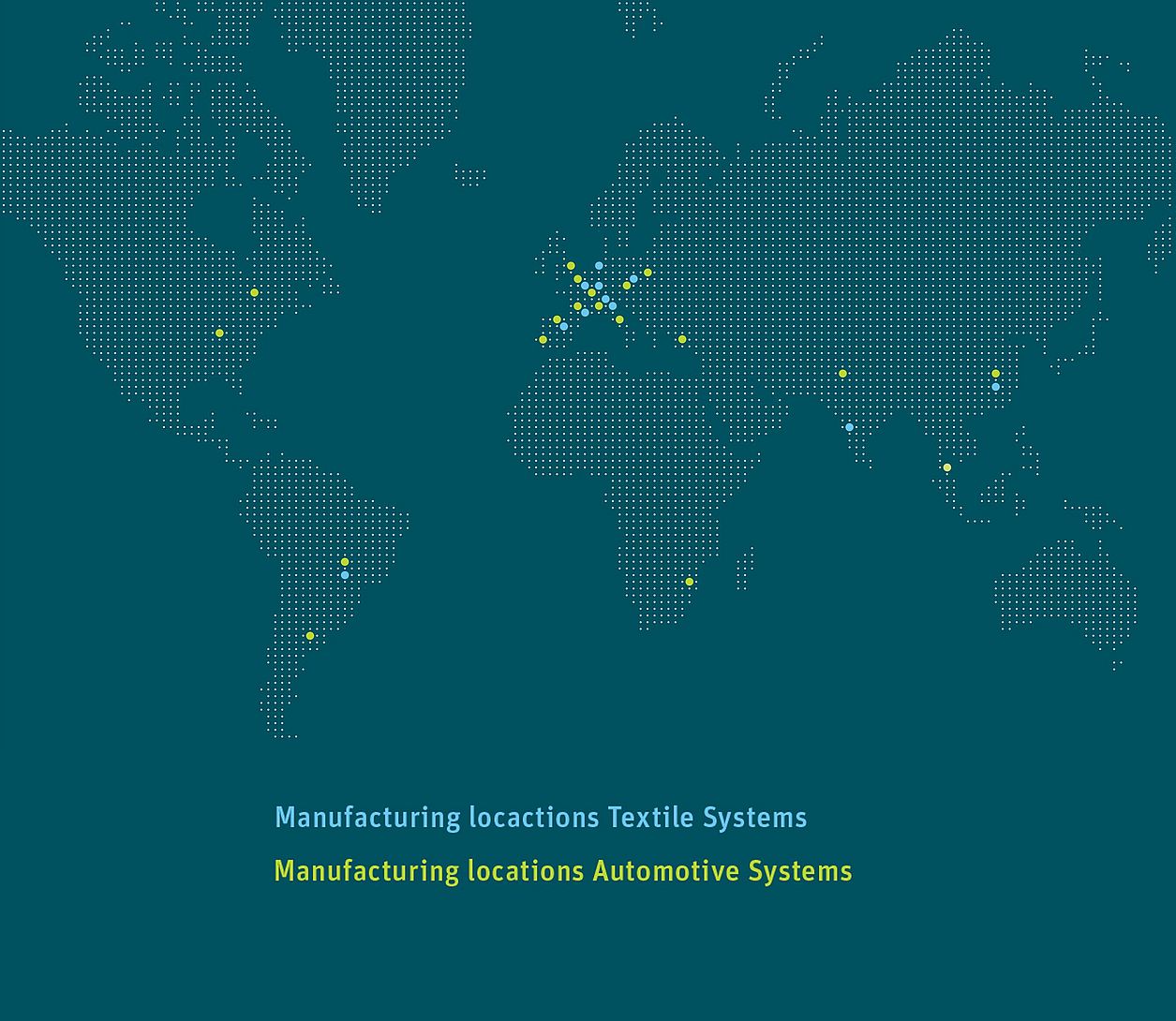

Rieter Textile: adapting to global market developments

Demand in the textile machinery business is subdued, and Rieter expects only slight growth in the medium term. Rieter adapts its capacities and starts by cutting around 700 jobs in Germany and Switzerland. By contrast, locations in Asia and Latin America are expanded.

Rieter Textile: acquisition in the field of technology components

Rieter takes over one of its top suppliers, Bräcker AG. Bräcker, based in Pfäffikon ZH, Switzerland, is a leading global supplier of rings and ring travelers – key components for ring spinning machines.

Rewarding long-term commitment: bonus system for managers expanded

Managers entitled to bonuses can now purchase Rieter shares on preferential terms. Two-thirds of these shares remain restricted for three years. By doing this, Rieter aims to promote awareness of long-term decision-making. The amount of the bonus is determined by the success of the Group and individual targets.

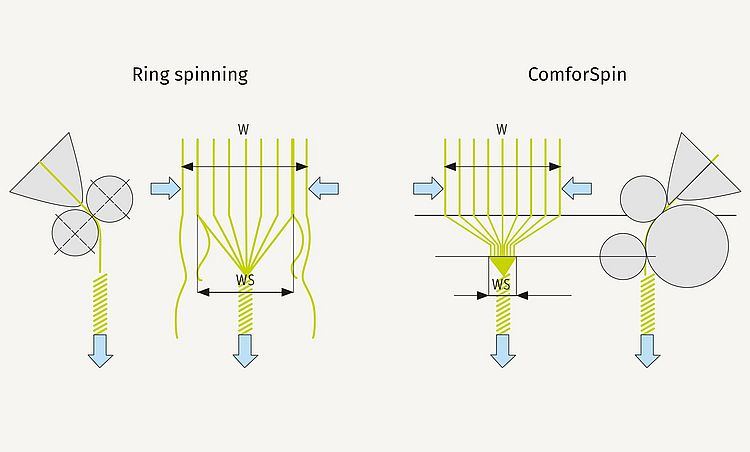

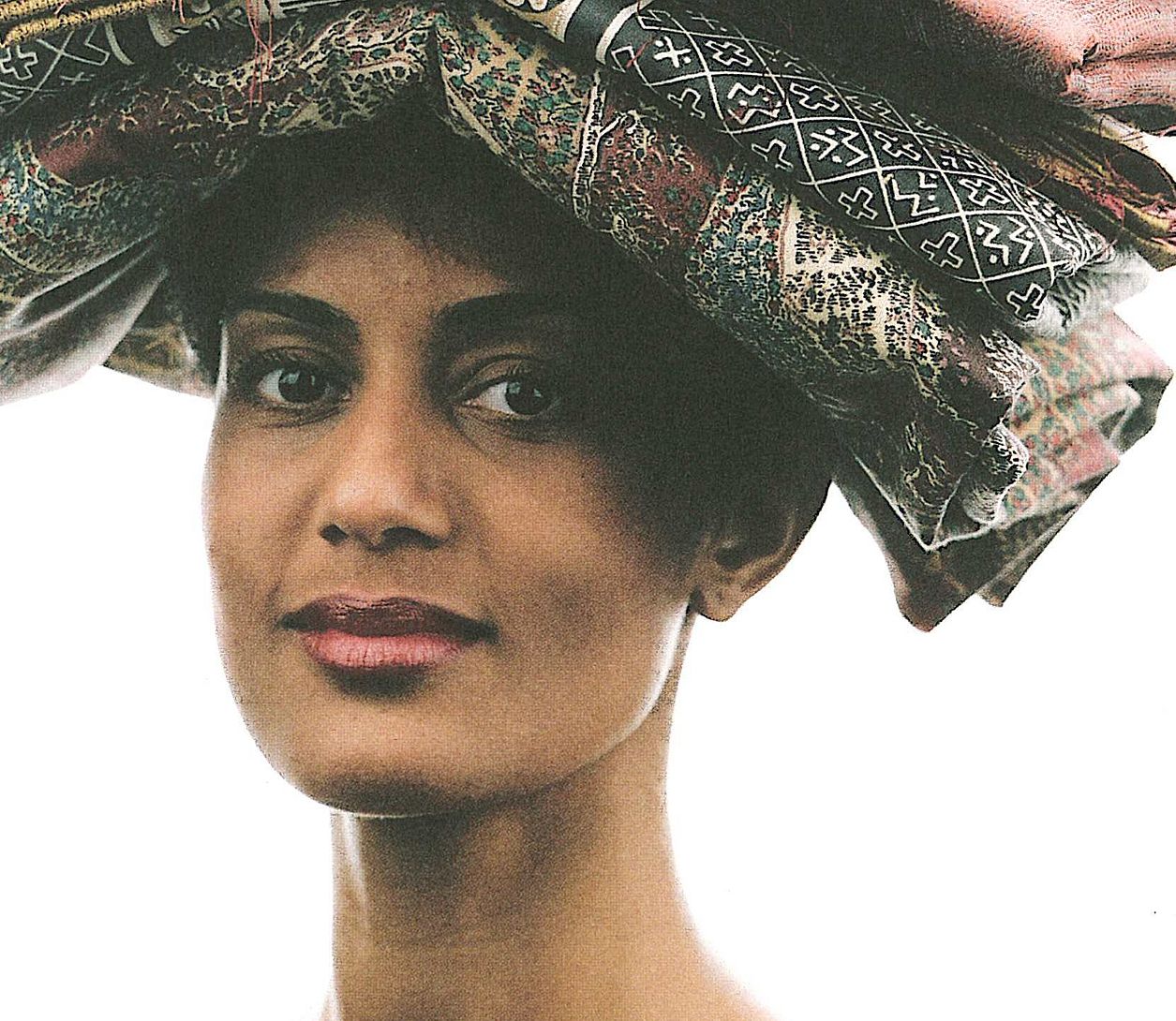

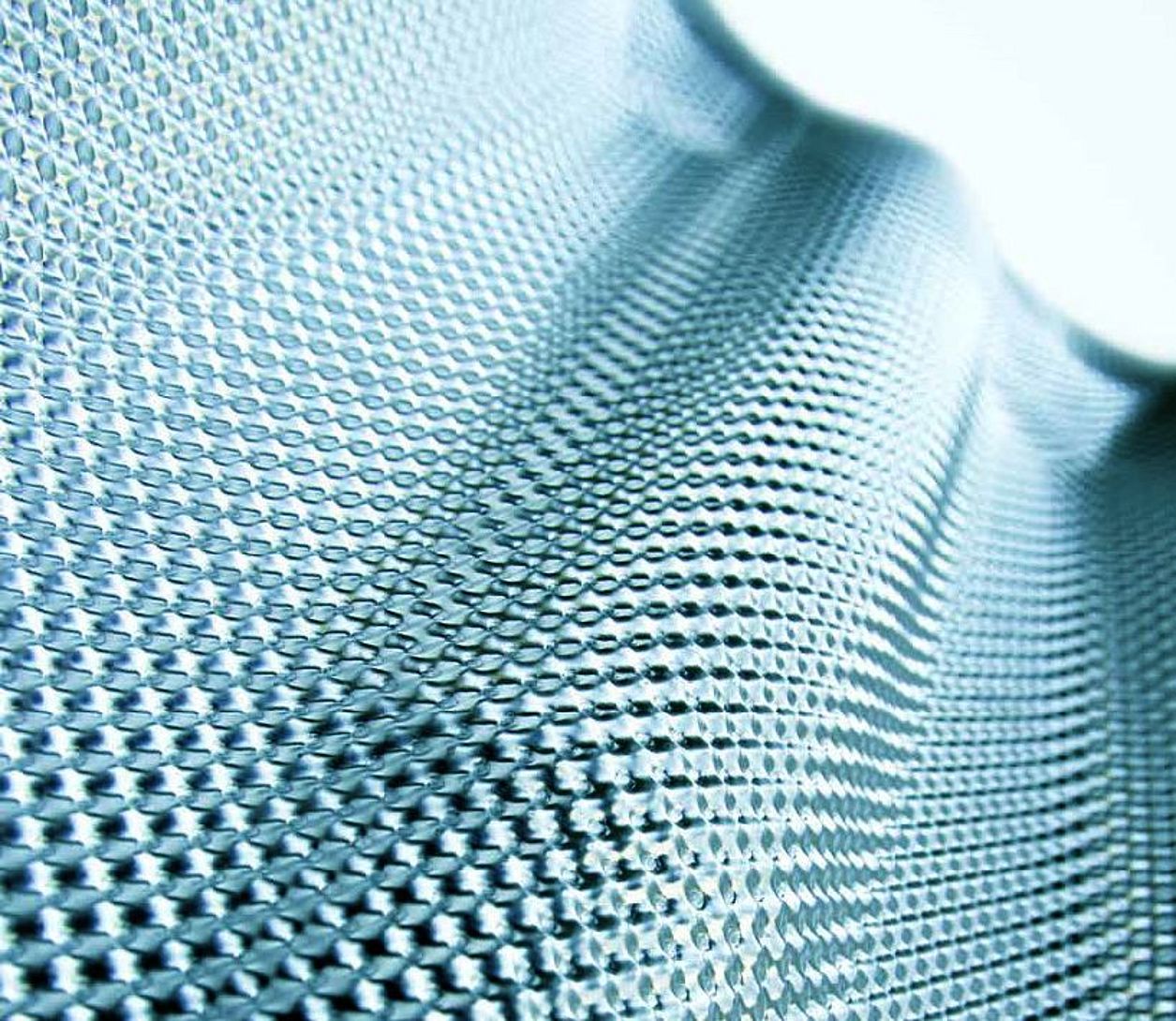

Rieter launches ComforSpin, a groundbreaking new spinning process

ComforSpin brings new momentum to the entire textile value chain. Machines with this compacting process enable the production of yarns with distinctly low hairiness and high strength. They provide benefits for further processing, which becomes more efficient, more environmentally friendly and more cost-effective.

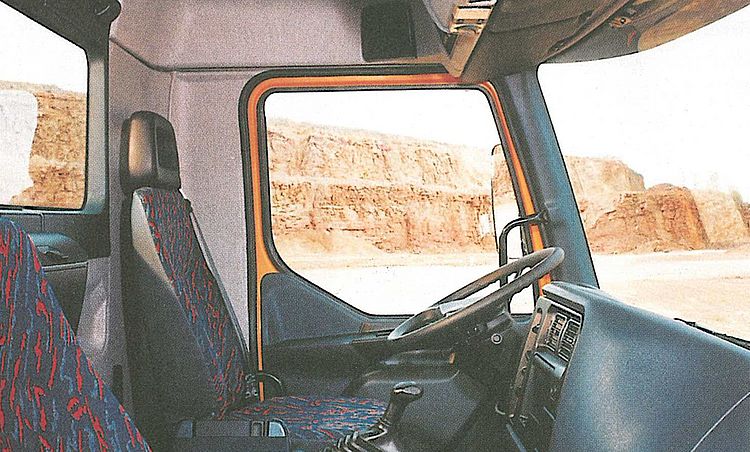

Rieter Automotive: functional carpets also for North America

In cars, the carpet doesn’t just create comfort – it also insulates against noise and heat from the engine compartment. By establishing a joint venture with major American manufacturer Magee, Rieter is able to offer this key product on both continents as the only automotive supplier.

Juli 1997

Rieter Automotive acquires Brazilian company Ello

Ello Ltda. is the leading manufacturer of acoustic, interior and heat protection systems in Brazil. The long-standing Rieter licensee supplies the plants of the major European and American car manufacturers in this important growth market – all of which are already Rieter’s customers.

The first environmental mission statement

Rieter has long been committed to the responsible use of resources and containing safety and environmental risks. To reinforce this commitment, Group management enacts an environmental mission statement that sets out globally applicable guidelines for employees and management.

«Asian crisis 1997/1998» – severe turbulence in emerging markets

The severe financial and currency crisis begins in Thailand in 1997 and spreads to other countries in the region. Triggered mainly by currency speculation, high indebtedness and structural problems in the financial sector, the crisis also inhibits investment in the textile industry.

Rieter Textile: crises in Asia and Russia lead to market collapse

In addition to the turbulence in Southeast Asian markets, Russia, an important export partner of the Turkish textile industry, suffers a severe economic crisis. Türkiye is one of Rieter’s key markets. Rieter has to cut further jobs in England, Germany and Switzerland.

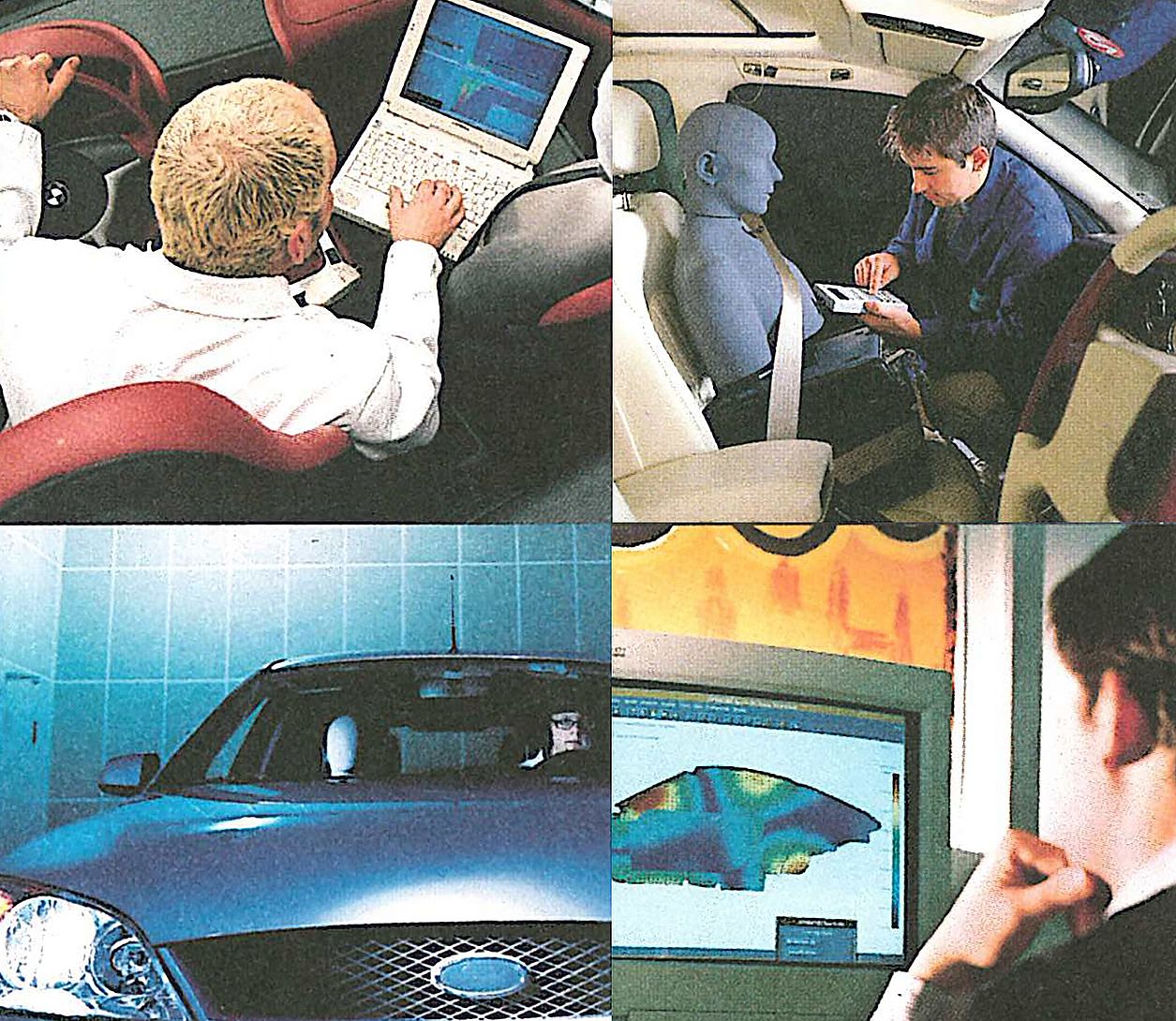

Rieter Ultra Light: pioneering innovation for vehicle construction

Weight reduction is one of the biggest challenges facing the automotive industry. The Rieter Ultra Light system for sound insulation is 30 to 60% lighter than conventional solutions and lowers costs while still achieving the same or better performance. An exclusive product with great potential.

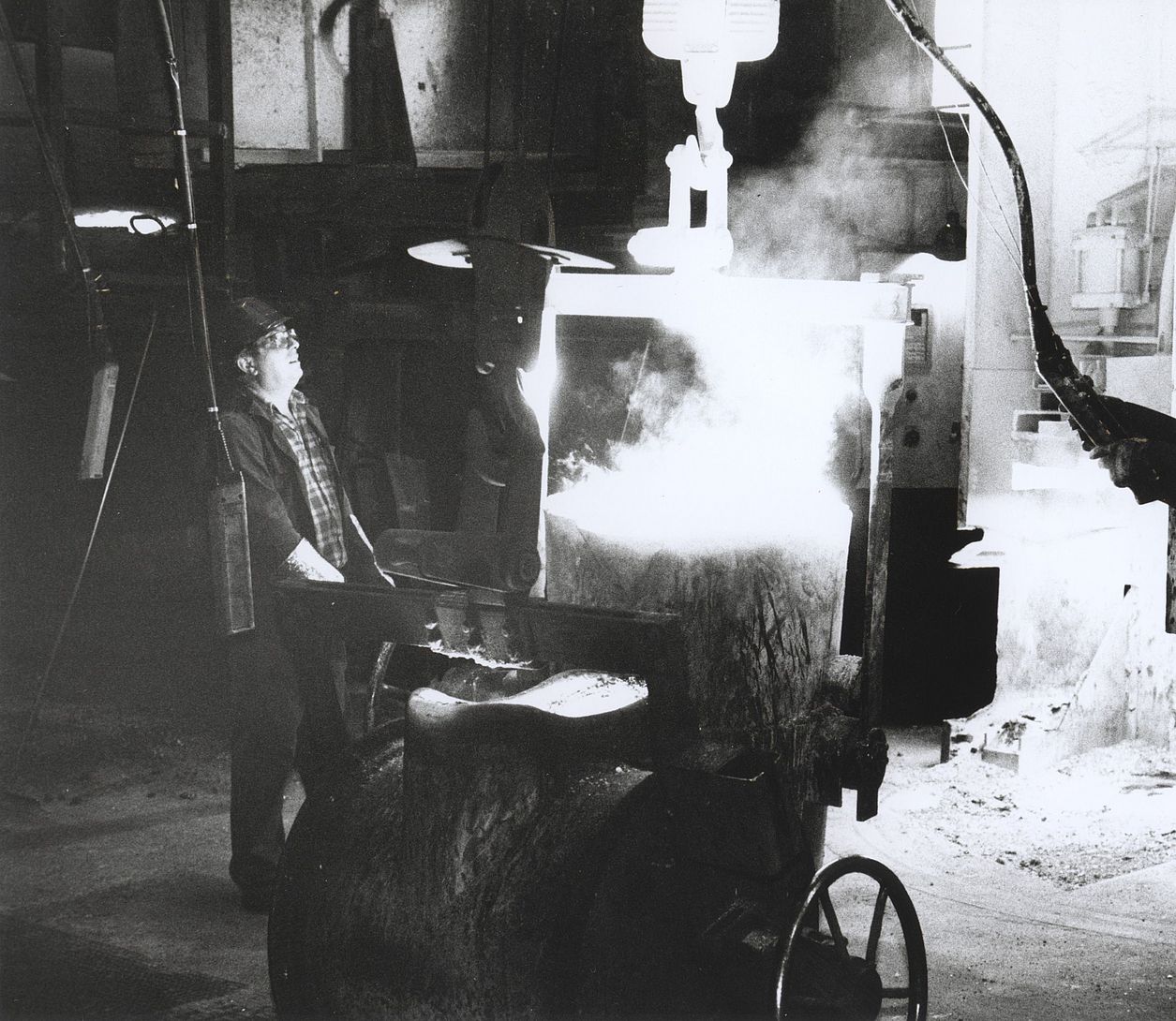

Furnace off: Rieter closes traditional foundry in Winterthur

Future generations of textile machines require considerably fewer castings. Rieter therefore prepares the foundry in Winterthur for closure and transfers the business to the Von Roll Group. This closes a chapter of the industrial history of this city.

1990s: companies and managers in focus of media and investors

The once sober business press is becoming more entertainment-focused and looking for stories about people. Major shareholders use this trend to exert public influence on listed companies. Companies have to adopt a more extroverted image and explain themselves.

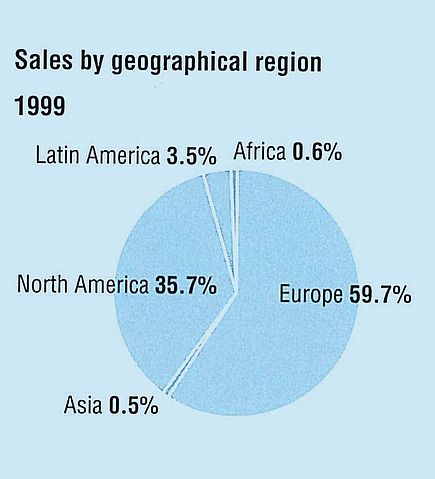

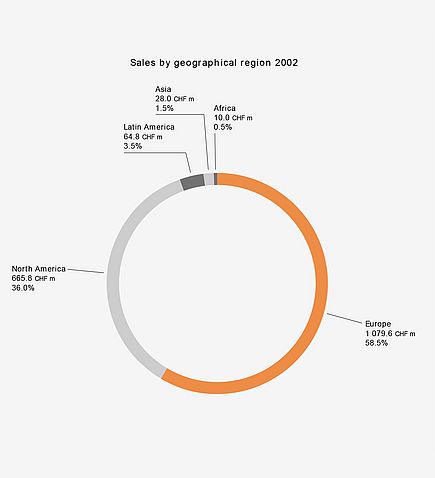

Group strategy proves its worth in adverse market environment

Economic crises in Asia and Latin America lead to historically low demand at Rieter Textile. Thanks to growth at Rieter Automotive, in addition to far-reaching structural measures, the Group is able to maintain its profitability. Across the Group, Rieter cuts 8% of all jobs.

ITMA 1999 in Paris: Rieter Textile with state-of-the-art product range

At the industry’s biggest trade fair worldwide, Rieter presents a range in which no machine is more than two years old. The continued strong interest in ComforSpin, a compact-spinning process, makes it clear that there is demand for groundbreaking innovations even in difficult economic conditions.

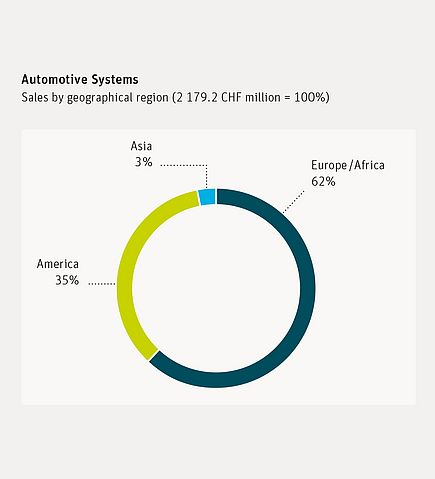

Rieter Automotive expands globally and restructures locations

Rieter Automotive is now also present in Poland, Türkiye and South Africa. Production of heat shields starts in the USA. Continuous adjustments are required in order to provide services at the optimal location. Five plants in Italy and the US are closed or sold.

Fear of the «Millennium Bug» – the year 2000 is just around the corner

Years are given in two-digit numbers in many older computer systems. It is feared that relevant systems in companies and administrations will crash at the turn of the millennium. This leads to large-scale Y2K projects around the world. When January 1, 2000, arrives, they are largely effective.

May 25, 2000

Kurt Feller takes over from Heinrich Steinmann as Chairman

At the Annual General Meeting, shareholders elect Kurt Feller, long-standing CEO and delegate of the Board of Directors, as Chairman. He replaces Heinrich Steinmann, who had been in office since 1994. The engineering graduate and former bank director is bid farewell with thanks for his valuable contribution.

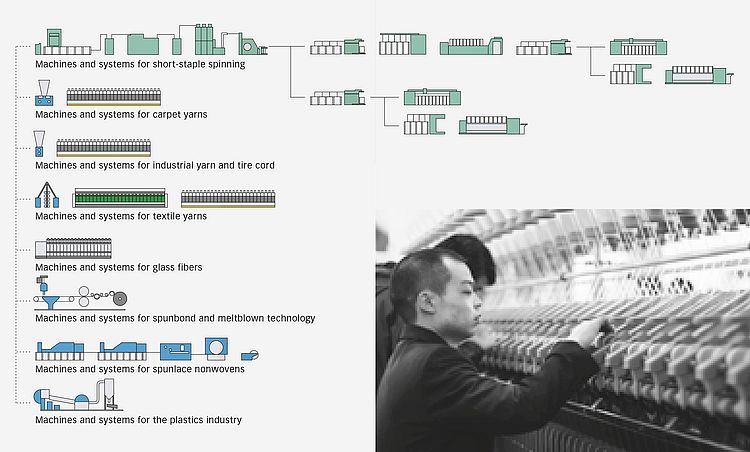

Rieter Textile: growth through market recovery and acquisition

After years in an unfavorable environment, Rieter benefits from a sharp upswing in the global market. In addition, Rieter takes over parts of the French ICBT Group with five locations worldwide. With this strategic step, Rieter opens up additional market segments in the synthetic fiber and nonwoven segments.

Rieter Automotive boosts know-how internally and through acquisition

Rieter works on new applications of the successful Rieter Ultra Light acoustic system. Computer-aided acoustic simulation and virtual engineering are also promoted. With a majority stake in the Italian I.DE.A Institute, Rieter boosts its know-how in automotive design.

Rieter Textile: significant acquisition in the components business

Rieter takes over several parts of the German Suessen Group. It has a strong position in rotor spinning technology and has also developed solutions in the field of compact spinning. Together with Suessen, Rieter becomes one of the world’s largest suppliers in the components market.

Rieter Textile mitigates risks of cyclical markets

With the acquisition of parts of the Suessen Group, Rieter strengthens its business with technology components, modernizations and services. These activities are far less affected by demand cycles than the machinery business. As a result, they enable more continuous growth.

Enron scandal leads to stricter regulations

The once highly respected US energy company Enron has massively manipulated its balance sheet for years. This revelation is followed by a gigantic bankruptcy. As a result, authorities around the world significantly tighten the reporting requirements for companies, including in Switzerland.

Rieter Group meets stricter reporting requirements

For the first time, Rieter publishes a separate chapter on corporate governance in its annual report. As a result of the Enron scandal in the US, the stock exchange regulator and the capital market place significantly tougher demands on the reporting of listed companies to ensure proper corporate governance.

May 7, 2002

Hartmut Reuter becomes CEO

On the date of the Annual General Meeting, Hartmut Reuter, previously Head of the Corporate Center, assumes the role of CEO. Up to that point, Kurt Feller, Chairman of the Board of Directors, also held operational responsibility for the Group. Kurt Feller now focuses exclusively on his duties as Chairman.

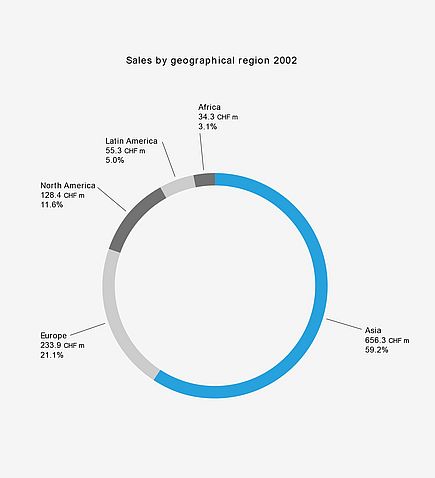

Rieter Textile: expansion of sales and production in China

Rieter expands its sales company in Shanghai to better serve the important Chinese market. The plant in Changzhou is also expanded. Furthermore, Rieter opens a sales office in the west of the country, an important center of the Chinese textile industry.

Rieter Automotive invests in further production facilities

Together with its North American partners, Rieter opens a plant in Canada and builds a site in Tennessee. Rieter also increases its stake in a Spanish joint venture. In order to achieve further growth, Rieter must continuously invest in the expansion of existing plants and establishing new ones.

Growing range of models: vans, pick-ups and SUVs in the fast lane

In North America, more light commercial vehicles are sold than passenger cars for the first time. The lifestyle segment is also growing faster in Europe. The variety of models is increasing worldwide. Suppliers have to innovate and be flexible with ever shorter development times – and that also applies to Rieter.

Rieter Textile: innovation for new markets

Following the relocation of manufacturing to the Czech Republic, India and China, Rieter sets up research and development centers in these countries. Customers in the new markets have different needs. Some local standards apply to production. It is carried out under different conditions and with different materials.

China: great desire for personal mobility

With the increasing prosperity of the Chinese population and a push for road construction, the demand for cars is rising sharply. In 2003, China becomes the world’s fourth-largest sales market for the automotive industry – after the USA, Japan and Germany.

Rieter Automotive leverages momentum in China

In order to exploit the opportunities in this expanding market, Rieter rapidly expands its presence. The company establishes a joint venture in southern China to supply Japanese car manufacturers from within the region. Rieter has been working successfully with its Japanese partner Nittoku in other markets for a long time.

Rieter Automotive: innovation with recyclable materials

In Europe, a vehicle model equipped with an innovative Rieter roof liner is launched on the market in large quantities. It is made of 100% recyclable fibers. As the automotive industry demonstrates increasing demand for such materials, they become a focus of innovation at Rieter.

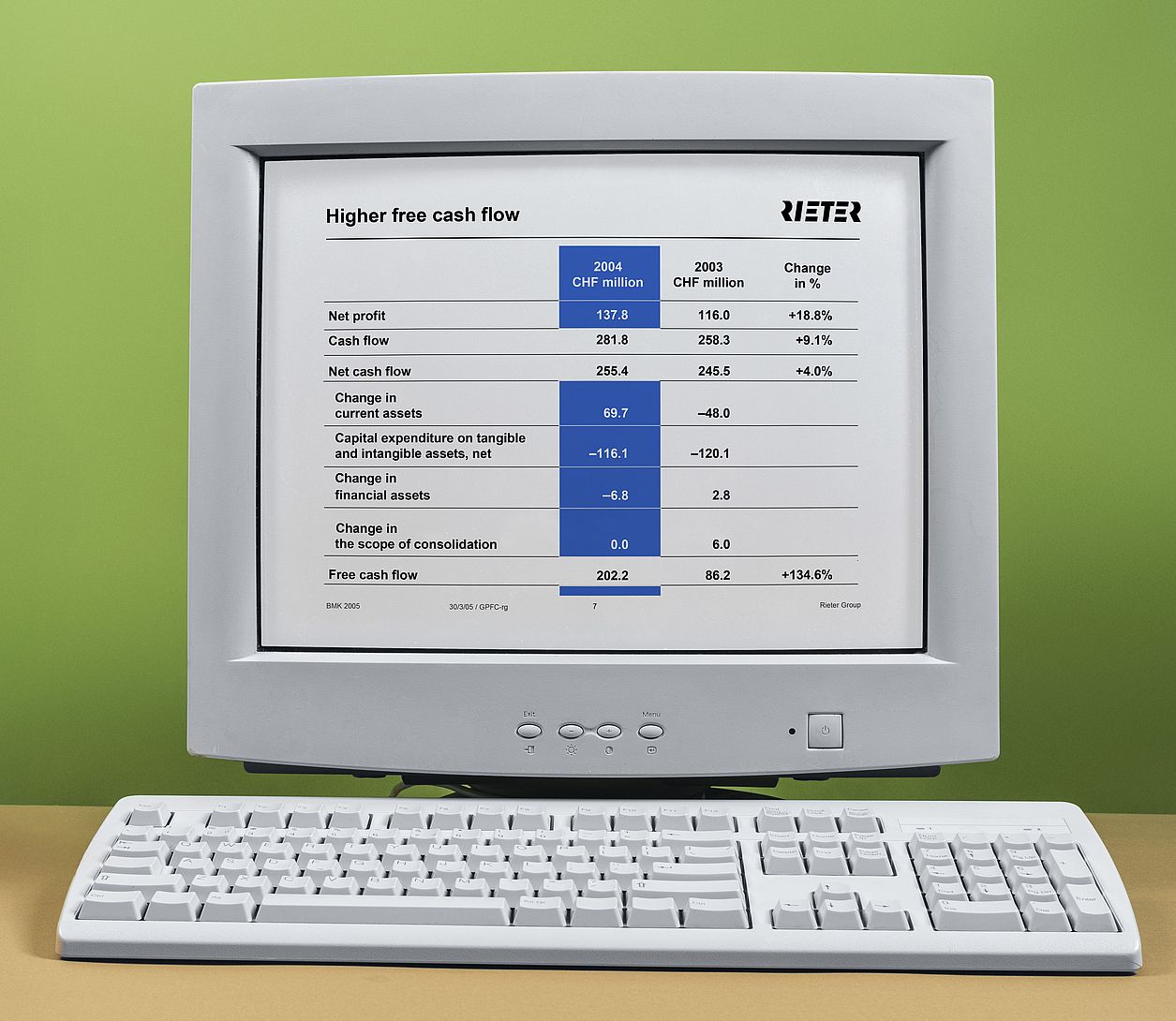

Rieter Group: solid financial basis for further growth

Rieter wants to continue to grow and generate good returns. This should primarily be achieved by internal efforts – through the success of attractive products. Equity ratio, net liquidity and a consistently solid cash flow facilitate acquisitions, which are nevertheless only made after careful consideration.

Rieter Textile: innovation and global presence fill the coffers

Rieter launches new machines in all business units, setting milestones in the industry and achieving very good returns. Key success factors include its global presence, control of the entire spinning process and long-term, reliable partnerships with customers.

Rieter Textile completes strategically important components business

With the acquisition of the Graf Group, headquartered in Switzerland, Rieter now offers the entire range of key components for the main spinning processes. The Graf Group is one of the world’s leading manufacturers of technology components in spinning preparation for the production of high-quality yarns.

Rieter Textile boosts resilience to strong fluctuations in the market

The components business is significantly less cyclical than the machinery business. To further strengthen the former, Rieter increases its stake in component manufacturer Suessen from 19 to 100%. In doing so, Rieter also acquires a plant in India and consolidates its position in this important market.

Rieter Automotive expands production in Eastern Europe

Rieter Automotive follows the car manufacturers to Eastern Europe and expands its existing production facilities in the Czech Republic. A second plant is about to open in Poland. The shift from west to east is due to cost reasons, but also attributable to the growing demand for cars in this region.

Kyoto Protocol raises awareness of greenhouse effect

The UN treaty, signed in Kyoto in 1997, enters into force in 2005 and obliges industrialized countries to reduce their greenhouse gas emissions. Regulations are tightened at regional level, including for the car industry.

Rieter Textile focuses on strategic strengths

Rieter has a strong portfolio of products for the three central processes of ring spinning, compact spinning and rotor spinning and is one of the global market leaders. Following a strategic review, Rieter decides to sell its existing synthetic fiber activities.

Auto industry: new markets growing, former key markets tailing off

Markets are shifting: globally, car production is increasing by 4%, while in Western Europe and North America it is declining. Eastern Europe now accounts for 23% of total production in Europe. In Asia, China is the fastest growing country at 26%, followed by South Korea at 8.6%. Other Asian countries are also developing.

Rieter Automotive aligns production with emerging markets

Automotive manufacturers demand low prices and a global presence from their suppliers. Rieter expects that future growth will mainly take place in Asia and Eastern Europe. While plants are being closed in North America, expansion progresses rapidly in Poland, Brazil, China and India.

Rieter Automotive: quality as a success factor

In North America, Rieter receives its 14th consecutive «Supplier of the Year» award from General Motors. Only Rieter and a German supplier have won this major award for high quality every year without interruption since its launch.

Rieter Group achieves new records in sales and earnings

Rieter is able to take advantage of the positive momentum of the global economy in both divisions. The focus on two industrial businesses present in all major economic regions is proving its worth. With targeted investments, Rieter sets the course for further profitable growth.

Rieter Textile acquires component manufacturer Berkol

Swiss company Berkol offers key components and service devices that ensure optimum operating behavior during the spinning process. Rieter intends to continue developing and producing components in Europe in the future. These high-quality and innovative products of European origin are in global demand.

Prosperity and consumption are growing in China

China has positioned itself as one of the strongest exporting nations in the world, especially for textiles. With the growing purchasing power of the Chinese population, there is now significant domestic demand for clothing and home textiles, placing new demands on the industry.

Rieter Automotive continues to expand in Eastern Europe and Asia

In line with its growth strategy, Rieter expands its location in Choceň, Czech Republic. Rieter opens its own plant in Chongqing, China. The two Chinese joint ventures that Rieter manages with Japanese company Nittoku are developing well. Rieter is now also gaining a foothold in South Korea.

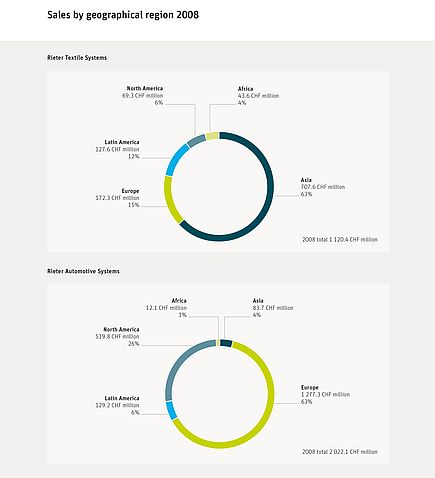

Rieter Group: global downturn causes slump in both businesses

After a record year in 2007, Rieter has to cope with an unprecedented slump in demand due to the global financial and economic crisis. For the first time since Rieter entered the automotive supply business in 1984 to balance out the cycles of textile machinery, both businesses hit a low at the same time.

Rieter Group: overcoming acute crisis, pursuing long-term goals

The marked downturn calls for radical measures to combat the erosion of profits, including short-time working and plant closures. At the same time, Rieter steadfastly pursues projects for long-term development. The company manages to maintain its strong market position despite an adverse environment.

Rieter Automotive with groundbreaking new fiber technology

The fiber-based technology Rieter Ultra Silent offers a unique benefit: due to the very low weight of the sound-insulating components, the CO2 emissions of vehicles are significantly reduced. The first underbody paneling using Rieter Ultra Silent goes into series production on time.

May 8, 2008

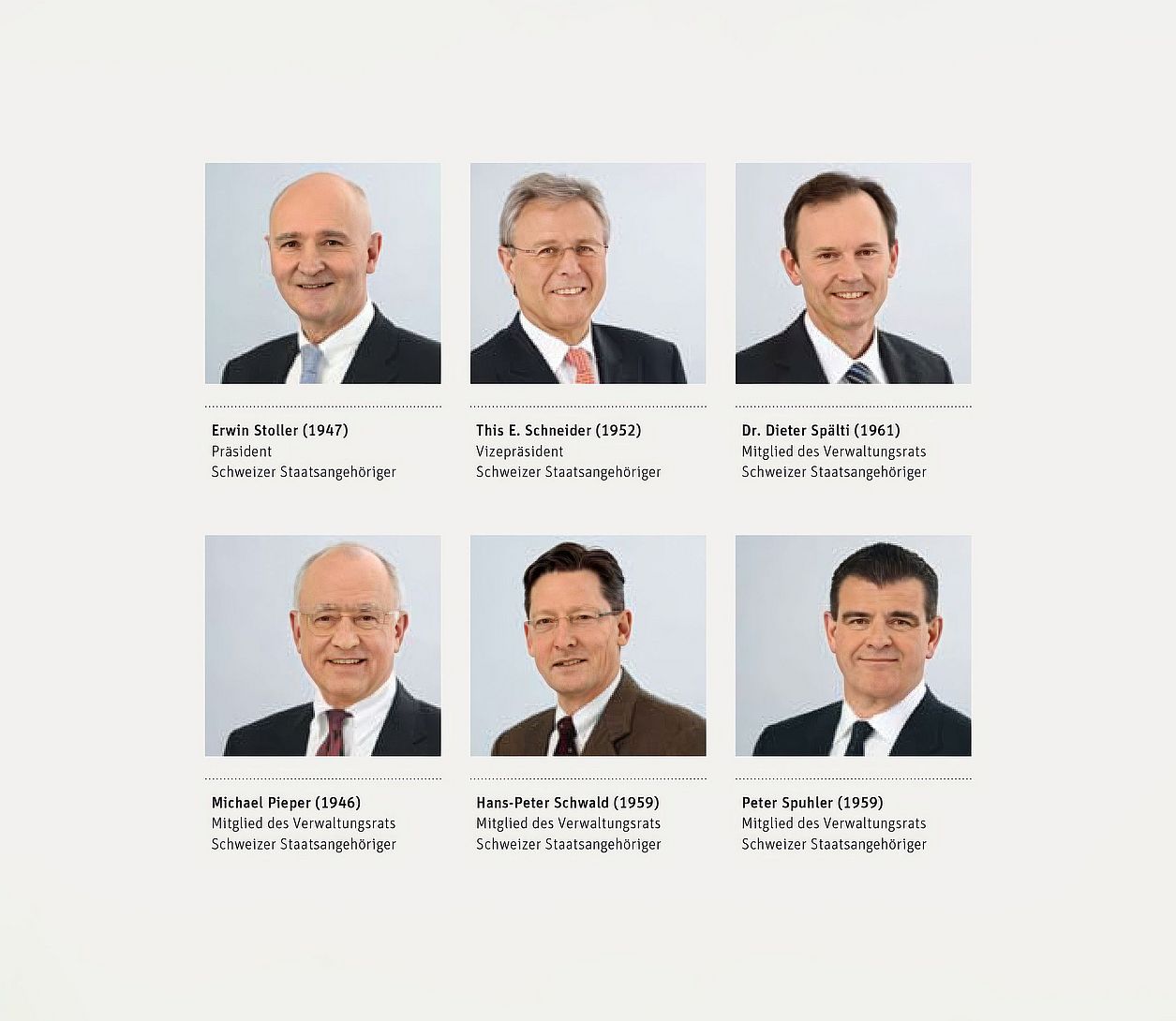

Chairman of the Board of Directors passes the baton

At the Annual General Meeting, Erwin Stoller is elected as a new member of the Board of Directors and as its Chairman. Erwin Stoller joined Rieter in 1978 and was a member of the Group’s Executive Board until the end of 2007. Kurt Feller, Chairman since 2000, retires with the company’s thanks.

September 15, 2008

Insolvency of US bank Lehman Brothers triggers global crisis

The prestigious investment bank, one of the largest in the world, has taken huge gambles in the real estate sector. Its bankruptcy triggers a dangerous global crisis of confidence among banks. As a result, far fewer loans are granted to companies. The financial crisis turns into an economic crisis.

Rieter Group passes the endurance test

The ongoing adverse market conditions lead to high losses, but Rieter is able to stem the negative momentum over the course of the year. Thanks to consistently implemented programs, Rieter successfully reduces costs and adapts global production capacities to the changed circumstances.

April 29, 2009

AGM elects industrial investors to the Board of Directors

As a result of the financial crisis, Rieter has to raise new equity capital. Investors Michael Pieper, This E. Schneider, Hans-Peter Schwald and Peter Spuhler assume corporate responsibility on the Board of Directors. This personal commitment in a difficult economic environment is welcomed by the Board of Directors.

August 2009

Change in the Group’s top management

Due to the difficult economic environment, Erwin Stoller, Chairman of the Board of Directors, also takes over operational management. In doing so, the Board of Directors assumes greater responsibility and shortens decision-making processes. Hartmut Reuter, CEO since 2002, departs with the company’s thanks.

Rieter Textile: localized products for India and China

Despite cost-saving measures, Rieter pushes ahead with innovations for growth markets. For example, Rieter launches a ring spinning machine that is manufactured in India for the domestic market. The production of a fiber cleaning machine is set up successfully in China and used as a model for further localization processes.

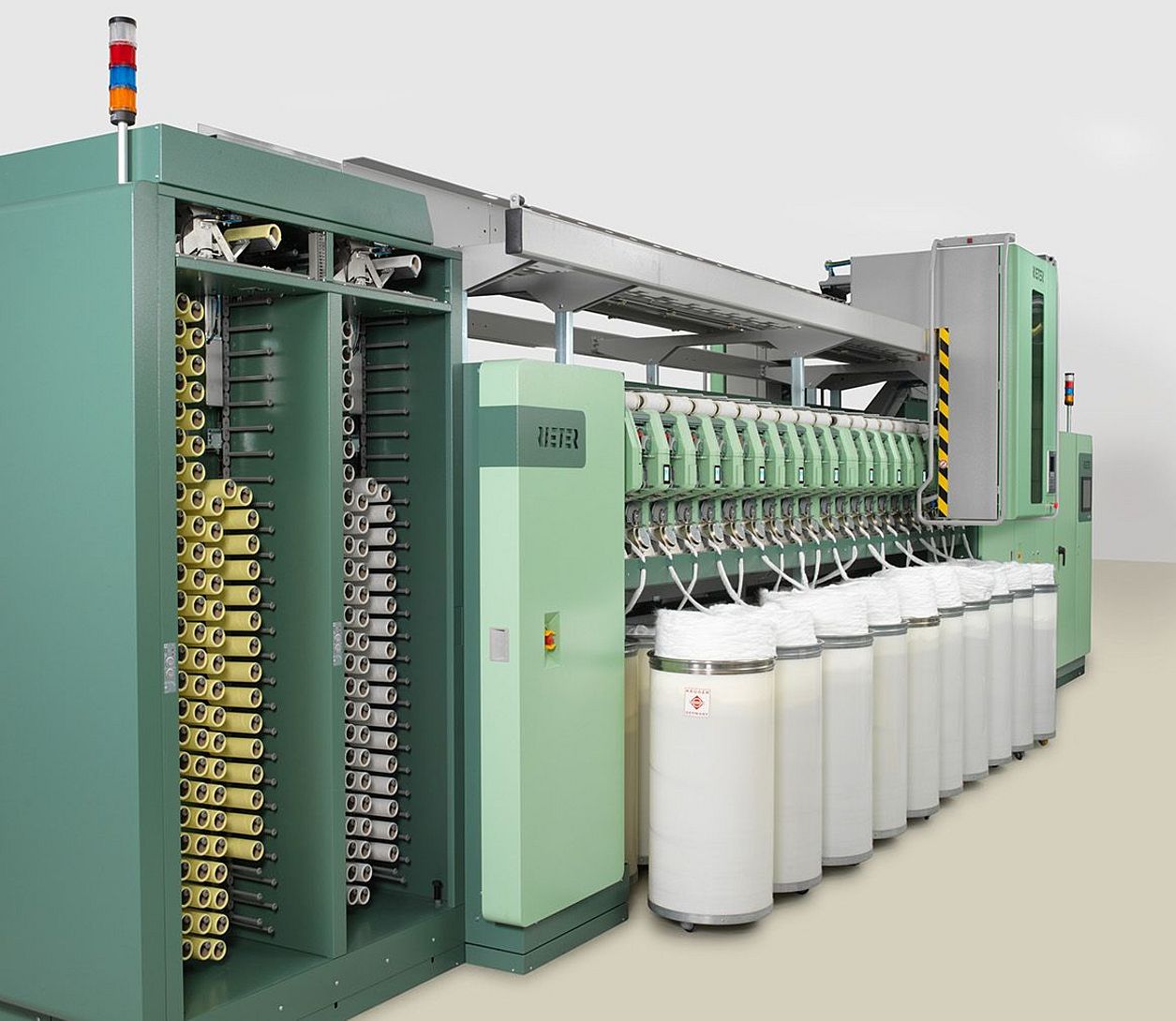

Rieter Textile: innovative air-jet spinning machine J 10 is launched

The air-jet spinning process enables a new yarn structure – attractive for processing and the final textile product. It is the most productive of all spinning technologies, with relatively low energy requirements. Rieter now offers four spinning technologies: ring, compact, rotor and air-jet spinning.

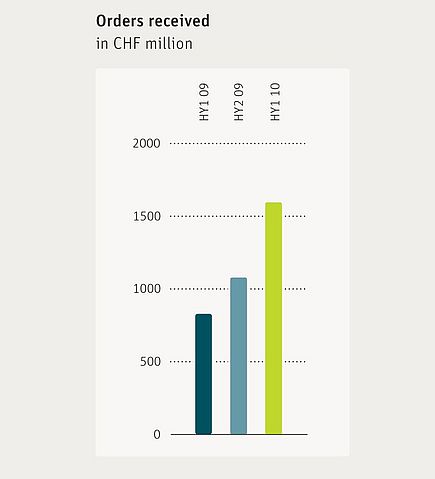

Successfully capitalizing on the upswing with attractive products

After two years in a very difficult environment, Rieter returns to profitability with a marked improvement in business performance sooner than forecast. Both divisions have positioned themselves well with a range of innovations and established products to capitalize on the upswing in their respective markets.

Rieter Textile: boom in orders and advantageous cost structure

With the upswing on the global market, Rieter achieves a boom in orders. After the two years of crisis, Rieter is even better able to handle market fluctuations. Greater efficiency and the production sites in Eastern Europe and Asia enable a more favorable cost structure.

Flexible working time models for a cyclical industry

Having a variety of working time models is a decisive factor in overcoming an economic downturn, but also the current sharp upswing. With the increase in orders, Rieter first abolishes short-time working and later relies on the commitment of temporary employees.

Auto industry: new regulations bring challenges and opportunities

At an international level, stricter laws force the automotive industry to make major changes in development and production. Low-emission and economical drive concepts as well as the containment of CO2 emissions and noise are required – offering great market potential for innovative suppliers such as Rieter.

April 13, 2011

Historic course set: the Rieter Group is to be split up

Companies that focus on one industry are more efficient to run and better accepted on the capital market than diversified ones like Rieter. The shareholders approve the Board of Directors’ proposal to split up the Group and list the automotive supply business separately on the stock exchange – under the name Autoneum.

May 13, 2011

Successful start for Rieter and Autoneum

With solid business figures assured and organizationally well prepared, both companies are ready to go it alone. In a friendly capital market, they get off to a successful start on the stock market. Rieter is now an industry-focused supplier of machinery and components for staple fiber spinning mills.

ITMA in Barcelona: machinery and component innovations

At the ITMA in Europe, the biggest trade fair in the industry, Rieter presents new products that are key to the spinning process. Optimum productivity, energy efficiency, good utilization of raw materials and a wide range of yarn properties for further processing and textile end products are in demand on the market.

Vocational training for India and China based on the Swiss model

The quality of Rieter products requires solid training of employees at all production sites. Rieter introduces the successful Swiss concept of young people learning a certified profession in the workplace over a period of several years in China and India – making them a pioneer in these countries.

September 6, 2011

Swiss franc now with minimum exchange rate of 1.20 per Euro

The euro was traded at 1.11 Swiss francs the previous day. In 2002, when the Euro was introduced, the rate was 1 to 1.48. The Swiss National Bank now introduces a minimum exchange rate. This will curb further appreciation of the Swiss franc and reduce the threat to the Swiss economy, including export companies like Rieter.

Expansion in Asia requires downsizing in Switzerland

Future growth will mainly take place in Asia. Rieter builds up capacity in this region to be closer to customers and adjusts capacity in Europe. This process involves job losses, partly achieved through natural fluctuation and early retirements.

Pleasing business performance, investment program brings success

Rieter is flourishing: the company significantly increases orders, sales and earnings. With the program for further growth launched in the previous year, Rieter is clearly improving its position in the Asian markets and achieving further important targets. The program is close to completion.

Investment program promotes new products and components

Targeted investments in 2012 and 2013 boosted innovation. Rieter launches energy, automation and performance innovations for all stages of the spinning process. These strengthen the company’s competitive position – both for customers and for Rieter.

Spotlight on a component: hidden hero

Rieter is awarded the «Watt d’Or» prize for the suction tube ECOrized. The Swiss government awards this innovation prize as a «quality seal for energy excellence». ECOrized, a key component for ring spinning machines, enables substantial savings in energy consumption.

New CEO sets new strategic targets

Erwin Stoller, former Executive Chairman, hands over operational responsibility to Norbert Klapper. Through the STEP UP program, the new CEO wants to boost innovation, expand the after-sales business and increase profitability. These three priorities are linked to financial targets.

April 9, 2014

More transparent remuneration for senior management

The Annual General Meeting approves a significant amendment to the Articles of Association: from 2015, shareholders will have to approve the framework for the remuneration of the Board of Directors and the Executive Committee annually in advance. This is demanded by a new Swiss law, which stems from a referendum.

Record deliveries – made possible by production sites in Asia

Significantly supported by the expanded capacities in China and India, Rieter delivers a record volume of around 2.33 million spindle equivalents worldwide, about 20% more than in the previous year. This is driven by large integrated systems and new markets, as well as market launches of innovative systems.

January 15, 2015

«Swiss franc shock» – minimum exchange rate of Swiss currency falls

The Swiss National Bank no longer finds the minimum exchange rate of CHF 1.20 per Euro introduced in 2011 justified. Its abolition comes as a surprise, and the Euro exchange rate falls abruptly. Products from Switzerland become markedly more expensive on the global market compared to competing products from the EU.

«Swiss franc shock» – drawback for Switzerland as an industrial center

The sudden appreciation of the Swiss franc causes the price of Swiss products to skyrocket for key sales markets. In order to reduce the export share and purchases in Swiss francs, Rieter aims to concentrate on the assembly of machinery in Winterthur.

April 2015

First technology center in China – a key element of Rieter’s portfolio

The first Rieter technology center in China is opened in Changzhou. The state-of-the-art spinning center facilitates activities such as spinning tests, training courses and technology trials. Customers in China and the surrounding markets can now benefit even more from Rieter’s leading know-how.

Oktober 2015

ITMA in Milan: innovation in digitization too

At ITMA Europe, the leading trade fair for the industry, Rieter launches a wide range of products. One highlight is SPIDERweb, an innovative control system. It is the only one on the market that can collect and analyze all relevant data about the entire process in a spinning mill and provide support in operation.

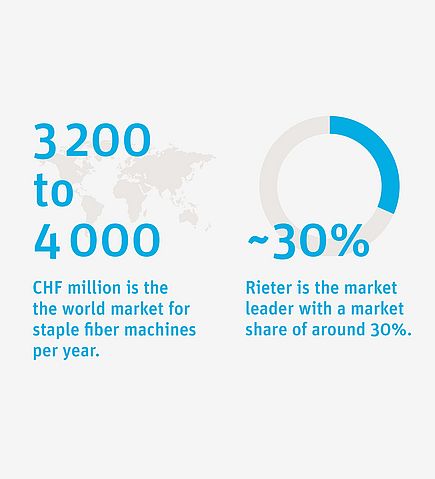

Rieter in a strong position with potential for further growth

Rieter supplies around 1.83 million spindle equivalents. This value is used to measure the capacity for yarn production. More than 250 million are in use worldwide. The relevant market for Rieter has an annual volume of between CHF 2.3 billion and CHF 4 billion. Rieter is the market leader with a share of around 30%.

China: Rieter offers solutions for spinning man-made fibers

Textiles made of man-made fibers and fiber blends hold a large share of the Chinese market. Rieter offers spinning mills suitable new solutions. For the first time in China, Rieter presents the J 26 air-jet spinning machine with a polyester option. Air-jet spinning is a particularly efficient process.

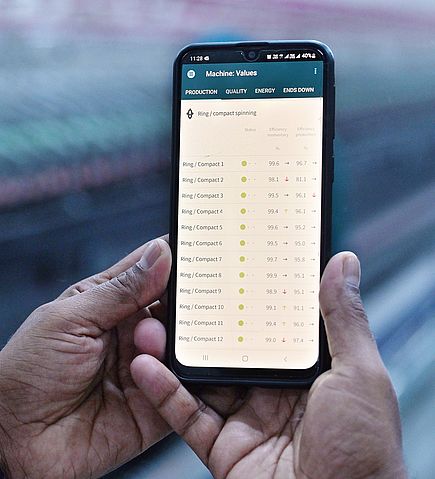

Digital expertise for spinning mills

With the UPtime Maintenance Solution, Rieter presents a digital expert system that optimizes the maintenance and monitoring of spinning mills. New features include an alarm module for rapid error detection and elimination, as well as a dashboard for data analysis independent of time and location.

November 4, 2016

Controlling global warming: Paris Convention enters into force

This agreement was adopted by almost all countries in the world in 2015. It promotes the development of green technologies. Companies listed on the stock exchange are also asked by investors to communicate targets and metrics for sustainable action and to report on developments annually.

April 5, 2017

Shake-up on the Board: Bernhard Jucker takes over as Chairman

The new Chairman Bernhard Jucker has been a member of the Board of Directors since 2016. The engineer brings extensive experience from top international positions to his role. His predecessor Erwin Stoller does not stand for re-election. After almost 40 years at Rieter, he departs with a warm farewell.

July 2017

Takeover of SSM: Rieter expands portfolio

SSM offers a wide range of machines and components used in the textile value chain – complementing Rieter’s products. The technology leader with a strong brand has plants in Switzerland, China and Italy and offers a range of services in over 60 countries.

October 2017

Rieter launches concept study for innovation center in Winterthur

The large-scale infrastructure for industrial production in Winterthur is no longer needed. A modern working environment for customer service, product and technology development, assembly and administration is planned for the site. Rieter continues to back Switzerland as business location and its innovation potential.

Production moves from Germany to the Czech Republic

Industrial production at the Ingolstadt site is no longer economically viable in the face of fierce global competition. Rieter decides to relocate production from Ingolstadt to existing Czech production sites. In Ingolstadt, Rieter will focus on the development of machines.

Market turbulence, strong product range

Uncertainty in Asia and Türkiye, as well as financing problems among customers in emerging markets, leads to a drop in orders. Thanks to a range of proven products and innovations in machinery and components, Rieter maintains its strong market position. The new SSM unit also contributes to this.

October 2018

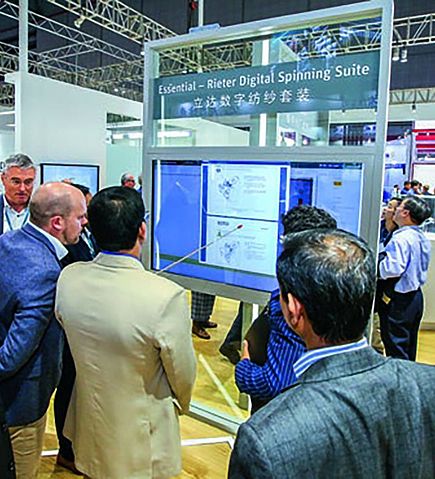

ITMA Asia in Shanghai: focus on digitization and systems

Rieter presents several world firsts at this important trade fair, including the ESSENTIAL platform. This platform visualizes optimizations for the entire spinning process at a glance. ESSENTIAL integrates Rieter’s digital products but is also open to customers’ systems.

Punitive tariffs lead to US/China trade conflict – with global repercussions

The US imposes new tariffs on goods from China and increases existing ones. By doing so, they aim to reduce their high trade deficit. The conflict between the two economic superpowers has a negative impact worldwide, especially on industrial supply chains.

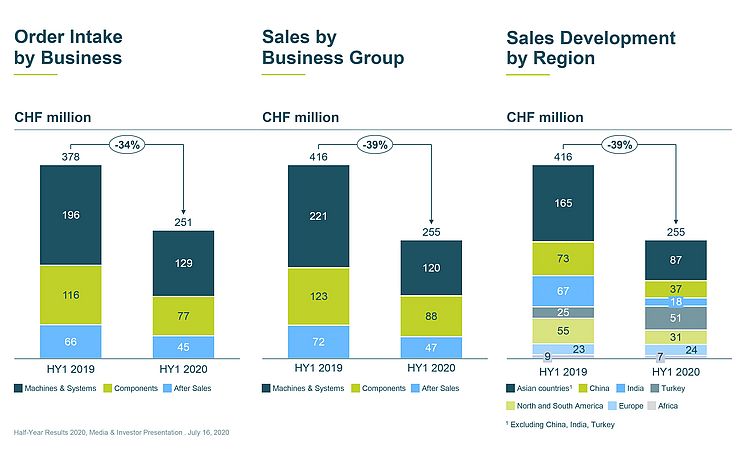

Year of contrasts: weak global market, successful innovations

The trade conflict between the US and China, overcapacity and political and economic uncertainties reduce sales performance in all regions, especially in key markets: by 32% in India and by 57% in Türkiye. In contrast, Rieter’s innovations are met with a positive response.

June 2019

ITMA in Barcelona: Rieter showcases an attractive new range

At the biggest industry trade fair, Rieter presents a comprehensive range of innovations for all four established spinning systems. The new products will enable customers to reduce their raw material, energy and labor costs, increase their productivity and flexibility, and develop new types of yarns.

June 2019

Rieter displays strength in the technology components business

At the ITMA in Barcelona, the five component manufacturers under the umbrella of the Rieter Group present their products at a joint stand for the first time. Customers appreciate this very much. The components from the Bräcker, Graf, Novibra, SSM and Suessen brands form a strong pillar of Rieter’s business.

September 2019

Germany: sale of property

Rieter sells the large factory site in Ingolstadt, Germany, which is no longer needed, to a company for project development. The transaction results in a substantial one-time profit contribution for the Rieter Group. The remaining employees will move to a new workplace.

COVID-19 pandemic leads to massive global economic downturn

The previously unknown coronavirus spreads worldwide and overloads the healthcare system. Due to lockdowns and travel restrictions, private consumption declines, supply chains are disrupted and unemployment rises. The pandemic causes the steepest decline in GDP since World War II.

Spring 2020

COVID-19 pandemic brings industry to a standstill

After the outbreak of the pandemic, many spinning mills around the world come to a standstill in the second and third quarters. Customers stop planned investments and ask Rieter to postpone deliveries. Order intake for the fiscal year plummets by 31%, sales by 25% and Rieter suffers a severe loss.

April 16, 2020

An unintentional premiere: Annual General Meeting without shareholders

To combat the pandemic, the Swiss government temporarily bans events. This also has consequences for Rieter’s Annual General Meeting, a popular event at the Winterthur location that’s steeped in tradition. Shareholders vote for once only by letter or electronically.

Safely navigating the pandemic with global crisis management

With carefully planned measures, Rieter manages to protect employees, secure liquidity, keep promises to customers, avoid disruptions in the supply chain and maintain services. Despite the difficult situation, Rieter continues its innovation program.

Orders at record level, but pandemic casts more shadows

After two difficult years, there is a striking catch-up effect: orders are up by 248%. But Rieter looks to the future with a degree of caution. The pandemic has not been defeated, the standstill at supplier companies has led to bottlenecks in supply chains, and drastic cost increases are stifling revenues.

Supply chain bottlenecks hold back the upswing

Many businesses around the world came to a standstill in 2020. There is now a shortage of various important materials in industry, especially microchips. In March 2021, the giant container ship Ever Given is stranded in the Suez Canal for days – triggering a chain reaction with enormous financial consequences.

August 2021

Milestone on the growth path: Rieter acquires parts of Saurer

Rieter complements its portfolio with three businesses from the Saurer Group – a large and important transaction. Of particular importance is the automatic winding machine from the Schlafhorst brand. It completes the Rieter ring and compact-spinning systems and further enhances their attractiveness.

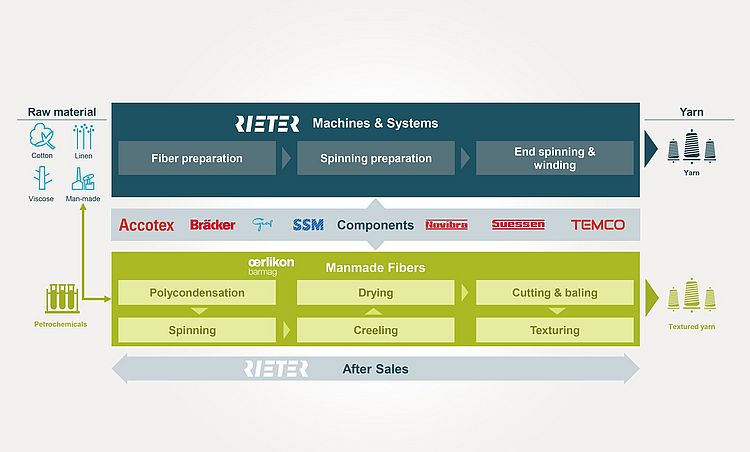

The brand family continues to grow

With the acquisition of Saurer business, Rieter gains two new brands with high-performance products in the components business: Accotex and Temco complement the existing Bräcker, Graf, Novibra, SSM and Suessen brands. As a result, this important revenue and earnings pillar of Rieter develops rapidly.

September 8, 2021

Foundation laid for Rieter CAMPUS at its headquarters in Winterthur

The project to repurpose the industrial site is taking shape. The Rieter CAMPUS will include a customer and technology center as well as an administration building. Rieter is creating a modern working environment, securing access to cutting-edge European technology and increasing its appeal for young talent.

January 1, 2022

Switzerland introduces new law for listed companies

Environmental, social and governance reporting requirements are expanded. Non-financial matters are now included, such as due diligence in supply chains, avoidance of child labor and ethical procurement of minerals from conflict areas.

Record sales, enormous operational challenges

Rieter increases sales by 56%. However, geopolitical uncertainties and the rapid rise in inflation and costs caused by material shortages reduce profitability. Rieter increases prices and develops new solutions with suppliers to be able to supply customers despite the bottlenecks.

Responsibility for the environment: promoting the circular economy

More than 100 certified Rieter experts offer repair services around the world. Rieter has introduced sustainable recycling processes in 27 of its own repair service centers in 22 countries. Each repair station can recycle all Rieter products that cannot be repaired.

Rieter backs AI – in the present and for the future

Artificial intelligence (AI) can help save energy and raw materials in the spinning process. For this purpose, Rieter offers the digital platform ESSENTIAL, among other things. Rieter and a Rieter-affiliated foundation finance a professorship at Winterthur University of Applied Sciences in order to expand its AI expertise.

Spring 2023

New CEO, new strategic program: Thomas Oetterli takes over

After nine years, CEO Norbert Klapper wishes to take on new challenges and is bid farewell with thanks. His successor, Thomas Oetterli, aims to strengthen sales, increase efficiency and quality in production, and relocate more resources to China and India with the Next Level program.

ITMA in Milan and Shanghai: new solutions, digital trade fair concept

At the two leading industry fairs, Rieter presents innovative solutions in the areas of digitization, automation and the circular economy. Experts present the machines, components and digital tools in a live demonstration at the fair and online in Rieter’s «Virtual Booth».

Sale of property in Winterthur successfully completed

Rieter sells the large site at its headquarters in Winterthur, which is no longer necessary for operations, to the Swiss real estate group Allreal. With a total area of around 75 000 m2, it achieves a purchase price of CHF 96 million. The new Campus is not part of this transaction.

Sustainability: non-financial targets examined and reported

For the first time, sustainability is an integral part of the Group’s reporting. Rieter communicates targets and metrics for non-financial matters. In 2023 Rieter makes progress in the areas of occupational safety, the proportion of women in management, CO2 emissions, and waste and recycling.

April 17, 2024

New at the top: Thomas Oetterli appointed Chairman of the Board

Chairman Bernhard Jucker reaches the statutory retirement age and is bid farewell with thanks. The Annual General Meeting elects Thomas Oetterli as his successor. He will continue in his role as CEO, which he took up in the previous year, to ensure the implementation of the Next Level program.

Summer 2024

Rieter moves into new headquarters on the Campus site in Winterthur

In addition to the Group headquarters, the striking new building houses the most advanced innovation and technology center of its kind. Here, Rieter pools the company’s know-how and maintains contact with customers from all over the world. The focus is on automation, digitization and artificial intelligence.

Sustainability: Rieter sets out on the path to net zero

Through the global Science Based Targets initiative (SBTi), Rieter commits to defining emissions reduction targets by 2040 that are consistent with science-based net zero targets. In doing so, Rieter assumes responsibility for its own actions and supports its customers on their sustainability journey.

New US President shapes the global economy with a «tariff hammer»

Donald Trump sets new economic policy priorities with global consequences. He wants to reduce the trade deficit and bring production that had been relocated abroad back to the US. To this end, he imposes import duties at constantly changing and varying levels, thus unsettling world trade.

May 6, 2025

Rieter acquires Barmag and expands market position with new division

Barmag is a global market leader for equipment to produce man-made fibers. With Barmag, Rieter strengthens its position in the textile industry and positions itself in the growing market for man-made fibers. The acquisition represents an important step in Rieter’s growth strategy.

The acquisition of the Barmag division is expected to be completed by the end of the 2025 financial year, subject to regulatory approval.

February 2, 2026

Rieter Completes Acquisition of Barmag

Rieter successfully completes the acquisition of Barmag as of February 2, 2026. This strategically important acquisition makes Rieter the world’s leading system provider for natural and synthetic fibers.